Services

EMA Clean-Caps

Specifically processed caps, ensuring a low content of particulate and bioburden contamination.

Packaging

Different packaging options adapted to your specific requirements.

Documentation

EMA guarantees the conformity and quality of each batch by providing different certificates.

Drug Master File (DMF)

Been registered at the US-FDA and Chinese FDA authorities for EMA’s Push-Off product range.

Project Development Service

Improving global product safety and ease of use is our absolute priority.

Additional services

We can provide complementary solutions thanks to our network of partner-companies.

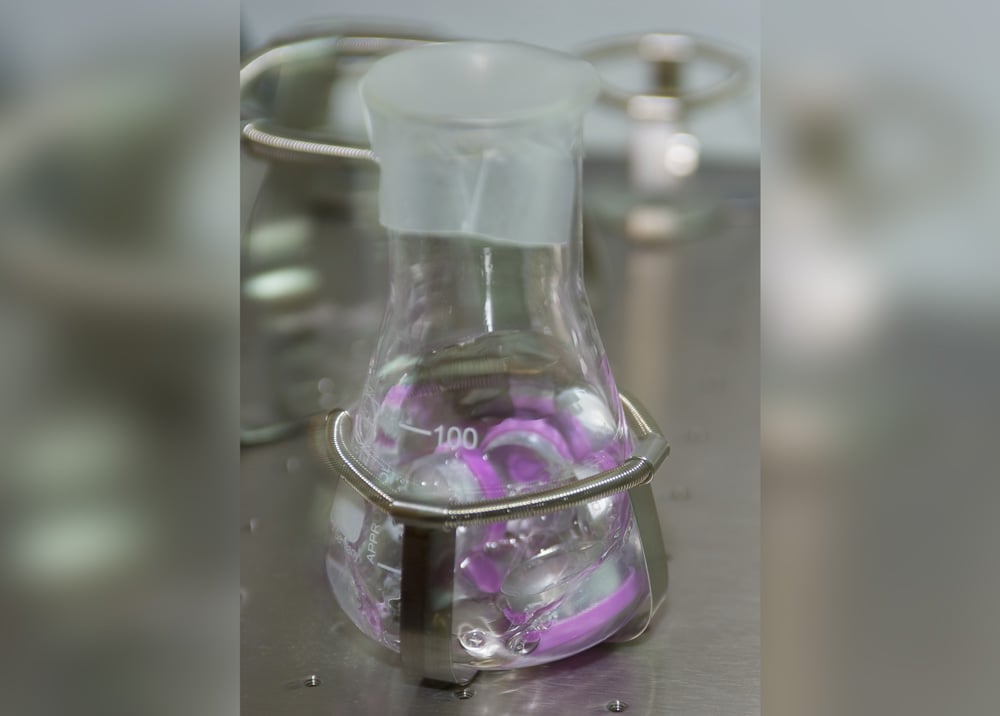

EMA CLEAN-CAPS

- EMA CLEAN-CAPS are specifically processed caps, ensuring a low content of particulate- and bioburden contamination before sterilization.

- EMA CLEAN-CAPS can be provided in “Ready-to-be-sterilized” or “Ready-to-be-used” versions.

- If the capping process happens inside the ASEPTIC CORE, the use of EMA CLEAN-CAPS is appropriate.

Packaging

- Polyethylene (PE) Bags

- Autoclavable TYVEK® Bags

- Double PE Bags

- PE Bag in Polypropylene Box

- RTP (Rapid Transfer Port)

Documentation

EMA Pharmaceuticals delivers :

- Certificate of Conformity (COC) systematically for each batch.

- Certificate of Analysis (COA) (optional)

- Certificate of Irradiation (COI) for caps “Ready-to-be-used”.

Drug Master File (DMF)

Project Development Service

Our priority is to improve global product safety and ease of use through design innovation, process improvement, and user convenience, customized to customers' specific needs, while keeping up with market and regulatory changes. Our Project Development Team is available to assist with any inquiries or studies regarding your project.

Additional services

Our network of partner-companies, at the cutting edge of their industry, allows us to provide you with a complete package of complementary solutions :

Additional services

Our network of partner-companies, at the cutting edge of their industry, allows us to provide you with a complete package of complementary solutions :

.jpg?width=974&height=746&name=9k=%20(1).jpg)